* Fully Automatic Core Cutting Line. One Hole Punch / Two V-Notch / One Swing Shear Two Machine Arms / 12 Panasonic Servo Motors * Compact Design. Only Require Space (11m x 2.5m) * Process all kind of transformer laminations. Vertical Step-Lap (3/5/7 Steps) Hybrid Step-Lap (3/5/7 Steps) Horizontal Step-Lap (3/4/5/6/7 Steps) Basic Design & Other Design * High Precision @ Tolerance +/- 0.10mm * On-Site Installation (One Week) On-Site Training (Two Weeks) * Warranty: Hardware (One Year) Software (Lifetime)

|

A) Introduction |

|||||||||||||||||||||||||||||||||||||||||||||||||||||

|

ST-420 is designed and built for the production of grain-oriented laminations suitable for the assembly of electric transformer cores with Step-Lap System and can cover up to a max sheet width of 420 mm. Consistently with the transformer design, this machine is particularly suitable for the production of cores for transformer power ratings ranging from 63.5 to 6000 KVA. The efficient and unique design of ST-420 has received the state patent. (China) Date: 2014/06/25 No: ZL201420054538.6 |

|

||||||||||||||||||||||||||||||||||||||||||||||||||||

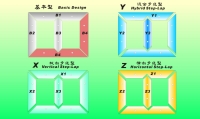

| (A1) 45' Step-Lap cuttings and 90' cuttings | |||||||||||||||||||||||||||||||||||||||||||||||||||||

|

* Vertical Step-Lap (X Design): 3/5/7 Steps. Upto 4 Holes * Hybrid Step-Lap (Y Design): 3/5/7 Steps. Upto 4 Holes * Horizontal Step-Lap (Z Design): 3/4/5/6/7 Steps. Upto 4 Holes. * 45' Conventional Design ( Basic Design): Upto 4 Holes. * 90' Strip Lamination: Upto 6 Holes Multi step-lap construction is well established as an industry standard where high efficiency transformers (using stacked cores) are required. It allows manufacturers to produce stacked core transformers with the lowest possible no-load loss, sound level and magnetizing currents while simultaneously reducing core assembly times and simplifying top yoke insertion. In short, it helps you (the manufacturer) to be more competitive.

Multi step-lap cores are highly effective in transformers where a high no-load loss evaluation is attached, particularly on 3-phase units. The no-load loss is usually 3-4% lower than single step lap (2 Steps) and 13-15% lower than Butt-Lap Design.

|

|

||||||||||||||||||||||||||||||||||||||||||||||||||||

|

(A2) ECO-Cutting (1% scrap reduced) |

|||||||||||||||||||||||||||||||||||||||||||||||||||||

|

* End-Coil Loss: 1.5 - 2.0 meter. * Machine Setting Loss: Standard and basic design before massive production for Steplap cutting. * Fill-Up Features: (StepLap Cutting) When cutting Steplap cores, the following situations will increase scrap losses. Material jammed: Due to bending material or slitting problems Coil Finished: End-Coil that is not possible to process. Power Goes Out: When electricity is not always stable. Fill-Up features is designed for cutting particular piece to make a complete steplap set. For example: When processing 5 steps of Yoke sheets, during the third piece the coil is finished. You are only getting 1, 2, 3 sheets. Fill-up feature allows you to process only 4 and 5 to make a complete set. |

|

||||||||||||||||||||||||||||||||||||||||||||||||||||

|

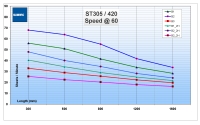

(A3) Speed |

|||||||||||||||||||||||||||||||||||||||||||||||||||||

|

* 51 sheets/minute = 859 Kg/Hr * Testing Standard: 1) ST-305 Speed at 99 (Range: 1-99) 2) Yoke without Hole 3) Size = 800x150mm 4) Thickness =0.30 (M5) * Note: Productivity depends on setting and cutting sizes. For more information, please refer to ST-305/420 Machine Output.pdf B1 = Yoke B2 = Side Limb B3 = Center Limb B1_2H = Yoke with 2 holes B2_2H = Side Limb with 2 holes B3_2H = Center Limb with 2 holes |

|

||||||||||||||||||||||||||||||||||||||||||||||||||||

| (A4) Wide Rage of Process Width, 40-420mm | |||||||||||||||||||||||||||||||||||||||||||||||||||||

|

* 40mm of coil width is the ST-420 minimum processing width, suitable for 50 and 63 KVA transformers.

* 420mm of coil width is the ST-420 maximum processing width, suitable for up to 6 MVA Power Transformers.

|

|

||||||||||||||||||||||||||||||||||||||||||||||||||||

| B) Main Components | |||||||||||||||||||||||||||||||||||||||||||||||||||||

| (B1) HMI (Human-Machine Interface) | |||||||||||||||||||||||||||||||||||||||||||||||||||||

|

* 15" Weintek (TAIWAN) i-Series Touch Screen. * Equipped with ARM9 400MHz CPU Greatly improve data processing and images display. * Language: English / Chinese For more information: http://www.weintek.com/globalw/Default.aspx# |

|

||||||||||||||||||||||||||||||||||||||||||||||||||||

|

(B2) PLC (Programmable Logic Controller) |

|||||||||||||||||||||||||||||||||||||||||||||||||||||

|

* Panasonic FP2 Series Scanning time of 1ms for 20k steps. With an operating speed at the top of its class, super high-speed processing is made possible. The result is a dramatically decreased tact time and high-speed device. For more information: |

|

||||||||||||||||||||||||||||||||||||||||||||||||||||

|

(B3) Panasonic Servo Motor |

|||||||||||||||||||||||||||||||||||||||||||||||||||||

|

* 12 Panasonic High-Speed Servo Motors Achieves 2kHz - the highest response frequency in the industry. In addition to its advanced control functions, the Panasonic Servo Motor features an LSI chip architecture that enables ultra-fast system operation. In view of its remarkable speed and superb positioning response, the Panasonic Servo Motor suitable for the most demanding systems. Furthermore, its outstanding response times drastically reduce vibration. Features a more compact motor that weighs considerably less. Both the large and the compact motor types have been overhauled, and the core has been successfully redesigned and scaled down. The integration of an innovative compact encoder has resulted in a 10% - 25% (1 - 6kg) motor weight reduction in the 1kW-and-larger class compared to conventional motors. For more information: https://www.panasonic-electric-works.com/eu/servo-drives-and-motors.htm |

|

||||||||||||||||||||||||||||||||||||||||||||||||||||

|

(B4) Tungsten Carbide Tool Sets |

|||||||||||||||||||||||||||||||||||||||||||||||||||||

|

* Tungsten carbide cutting tools are very abrasion resistant and can also withstand higher temperatures than standard high speed steel tools. Tungsten carbide tools maintain a sharp cutting edge better than other tools, they generally produce a better finish on parts, and their temperature resistance allows faster machining. * All cutting tools on ST-305/420 are made by the industry best tungsten carbide that will guaranty 200,000 cuts before next grinding. For more information: ST-305 Tools Set Alloy Testing Report. |

|

||||||||||||||||||||||||||||||||||||||||||||||||||||

|

(B5) Cutting Units |

|||||||||||||||||||||||||||||||||||||||||||||||||||||

|

* One Hole Punch Unit One CNC-longitudinally adjustable hole punch unit provides a high accuracy output. (Dia 8 to 35mm / optional ) * Two V-Notch Units 2V-Notch Units with motorized cross movement on CNC-longitudinally base.

* One Swing Shear Japanese SUMITOMO Motion control drives that give zero backlash, minimal lost motion and high torsional stiffness. These reducers excel in applications that demand accurate positioning. Small hysteresis loss. High efficiencies and low vibration. For more information: SUMITOMODRIVE

|

|

||||||||||||||||||||||||||||||||||||||||||||||||||||

|

(B6) Other Components |

|||||||||||||||||||||||||||||||||||||||||||||||||||||

|

* Ball Screw Assemblies, Rexroth , From Germany. More Info Rexroth Ball Screw Assemblies do not only work with greater levels of accuracy and at higher speeds, they can also be supplied at very short notice. A wide range of precision screws and preloaded or adjustable-preload single and double nuts is available for all feeding, positioning and conveying tasks.

* Linear Guideway, HIWIN , From TAIWAN. More Info Low Noise Design With SynchMotion TM technology, rolling elements are interposed between the partitions of SynchMotion TM to provide

improved circulation.

* SERVO MOTOR GEARHEAD, SESAME, From TAIWAN. More Info

|

|

||||||||||||||||||||||||||||||||||||||||||||||||||||

|

C) Service and Payment Terms |

|||||||||||||||||||||||||||||||||||||||||||||||||||||

|

(C1) Overseas Standard Packing |

|||||||||||||||||||||||||||||||||||||||||||||||||||||

| * Guarantee: No scratch

and rust during long-range transportation 1) Applying Anti-Rust Oil 2) Covering with stretch Film 3) Covering aluminum air bag 4) Vacuuming air bags 5) Boxing all the pallet 6) Loading to the Container |

|

||||||||||||||||||||||||||||||||||||||||||||||||||||

| (C2) Parts and Accessory | |||||||||||||||||||||||||||||||||||||||||||||||||||||

* Above items will be included in oversea project. |

|

||||||||||||||||||||||||||||||||||||||||||||||||||||

| (C3) Service / Warranty | |||||||||||||||||||||||||||||||||||||||||||||||||||||

| * Service Centers are available in India, China and Taiwan. Customers in these region can receive quick support and service. We also give quick response to customers in other region by on-line training or sending engineer on-site. * We offer On-Site Installation (One Week) On-Site Training (Two Weeks) * Hardware Warranty: One Year Software Warranty: Lifetime |

India Service Center |

||||||||||||||||||||||||||||||||||||||||||||||||||||

| (C4) Payment Terms | |||||||||||||||||||||||||||||||||||||||||||||||||||||

| * Terms: T/T 40% Deposit 50% Before Shipment 10% One Month After Installation |

|||||||||||||||||||||||||||||||||||||||||||||||||||||

| Model | ST-305 | ST-420 |

| Coil Width (mm) | 40-305 | 40-420 |

| Thickness (mm) | 0.18- 0.35 | 0.18- 0.35 |

| Hole Size (mm) | 8-22 | 8-22 |

| Speed (m/min) | 0-120 | 0-120 |

| Accuracy (mm) | +/- 0.2 | +/- 0.2 |

| Shearing burrs (mm) | ≤0.02 | ≤0.02 |

| Servo Motor | 12 | 12 |

| Hole Punch | 1 | 1 |

| V Notch | 2 | 2 |

| Swing Shear | 1 | 1 |

| Magnetic Arm | 2 | 2 |

| Size: Main Unit (LxWxH) mm | 2750x1300x1800 | 3120x1660x1800 |

| Size: Stacker (LxWxH) mm | 2550x1400x1600 | 3450x1890x1600 |

| Size: DeCoiler (LxWxH) mm | 1510x920x1350 | 1510x920x1350 |

| Floor Space (LxW) meter | 8 x 2 | 9 x 2.5 |

| Language | Chinese/English | Chinese/English |

| Power Required | 380VAC 50/60Hz (6KW) | 380VAC 50/60Hz (8KW) |