* Fully Automatic Strip Lamination Core Cutting Line * High Reliability and Compact Design * Low Operating Cost: Tooling and Maintenance * High Precision @ Tolerance +/- 0.01mm * Training 2 Days) * Warranty: Hardware (One Year) Software (Lifelong)

|

A) Introduction |

|||||||||||||||||||||||||||||

|

SL-200 and SL-300 are designed and built for cores of small transformers such as Inverters and UPS that made of Grain Oriented or Non-Grain Oriented Silicon Steel to cut 90° shapes (Strip Laminations). MAIN features are:

|

|

||||||||||||||||||||||||||||

| (A1) 90° Strip Laminations Cuttings | |||||||||||||||||||||||||||||

|

* With Holes: Hole Size: 6mm - 25mm Hole Number: 15 Holes (Max) Length: 20-2000mm ______________________________________________________________ Without Hole: Length: 20-2000mm

|

|

||||||||||||||||||||||||||||

|

(A2) Lamination Cutting Speed |

|||||||||||||||||||||||||||||

|

At 95% of Maximum Speed (Range: 1-99) Lamination Size: 80mm X 250mm / Thickness =0.35mm No Hole = 110 Piece/Minute = 2,880 KG/ 8 hrs One Hole = 58 Piece/Minute = 1,520 KG/ 8 hrs Two Holes = 38 Piece/Minute = 996 KG/ 8 hrs Three Holes = 30 Piece/Minute = 786 KG/ 8 hrs

|

|

||||||||||||||||||||||||||||

| B) Main Components | |||||||||||||||||||||||||||||

| (B1) HMI (Human-Machine Interface) | |||||||||||||||||||||||||||||

|

* 7" MCGS Touch Screen. * Equipped with Cortex-A8 CPU Greatly improve data processing and images display. * Language: English / Chinese |

|

||||||||||||||||||||||||||||

|

(B2) PLC (Programmable Logic Controller) |

|||||||||||||||||||||||||||||

|

* Delta (TAIWAN) DVP-E series Programmable logic controller (PLC) is a control system using electronic operations. Its easy storing procedures, handy extending principles, functions of sequential/position control, timed counting and input/output control are widely applied to the field of industrial automation control. With an operating speed at the top of its class, super high-speed processing is made possible. The result is a dramatically decreased tact time and high-speed device. |

|

||||||||||||||||||||||||||||

|

(B3) Servo Motor |

|||||||||||||||||||||||||||||

|

* Three Delta (TAIWAN) High-Speed Servo Motors To meet the demanding requirements of motion control applications in industrial automation and satisfy the needs of high-precision positioning control requested by machine designers and system integrators, Delta provided the high-performance motion control ASDA-A2 series servo motors and servo drives in 2013. Features a more compact motor that weighs considerably less. Both the large and the compact motor types have been overhauled, and the core has been successfully redesigned and scaled down. The integration of an innovative compact encoder has resulted in a 10% - 25% (1 - 6kg) motor weight reduction in the 1kW-and-larger class compared to conventional motors. |

|

||||||||||||||||||||||||||||

|

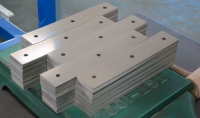

(B4) Shear Unit (Tungsten Carbide) |

|||||||||||||||||||||||||||||

|

Shear Unit on SL Series is made by the industry best tungsten carbide that will guaranty 50,000 cuts on each time blade grinding. * Tungsten carbide cutting tools are very abrasion resistant and can also withstand higher temperatures than standard high speed steel tools. Tungsten carbide tools maintain a sharp cutting edge better than other tools, they generally produce a better finish on parts, and their temperature resistance allows faster machining. |

|

||||||||||||||||||||||||||||

|

(B5) Hole Punching Unit (Tungsten Carbide) |

|||||||||||||||||||||||||||||

|

* Hole Punching Unit Special Design, easy to operate and adjustable hole punch unit. (Size 8 to 25mm / optional )

-------------------------------------------------------------------------------------

* Easy to Operate and Maintain 4 precision Guiding poles and Special Design of Die Set make hole punching and maintenance became simple and easy. No special trained engineer required.

|

|

||||||||||||||||||||||||||||

| (B6) Others | |||||||||||||||||||||||||||||

|

* Lamination Holder and Centering Adjusting Unit.

-------------------------------------------------------------------------------------

* Precise Feeding Rollers (Master / Slave) attached to Servo Motor.

|

|

||||||||||||||||||||||||||||

|

AC Voltage Regulator (4KVA) |

|

||||||||||||||||||||||||||||

|

C) Major Units for SL-200 / SL-300 Core Cutting Line |

|||||||||||||||||||||||||||||

| (C1) De-Coiler System | |||||||||||||||||||||||||||||

|

* De-Coiler Machine is equipped with De-Burring and Leveling unit.

|

|

||||||||||||||||||||||||||||

| (C2) S-Holding Table | |||||||||||||||||||||||||||||

| S-Holding Table is made by Stainless Steel to avoid dust. |  |

||||||||||||||||||||||||||||

| (C3) Cutting Unit | |||||||||||||||||||||||||||||

| * SL200 / SL300 Main Unit. |  |

||||||||||||||||||||||||||||

| (C4) Stainless Table | |||||||||||||||||||||||||||||

|

* Use for packing and stacking.

|

|

||||||||||||||||||||||||||||

|

D) Service and Payment Terms |

|||||||||||||||||||||||||||||

|

(D1) Overseas Standard Packing |

|||||||||||||||||||||||||||||

| * Guarantee: No scratch and rust during long-range transportation 1) Applying Anti-Rust Oil 2) Covering with stretch Film 3) Covering aluminum air bag 4) Vacuuming air bags 5) Boxing all the pallet 6) Loading to the Container |

|

||||||||||||||||||||||||||||

| (D2) Parts and Accessory | |||||||||||||||||||||||||||||

|

|

||||||||||||||||||||||||||||

| (D3) Service / Warranty | |||||||||||||||||||||||||||||

| * Service Centers are available in India, China and Taiwan. Customers in these region can receive quick support and service. We also give quick response to customers in other region by on-line training or sending engineer on-site. * We offer Training (Two Days) * Hardware Warranty: One Year Software Warranty: Lifetime |

|

||||||||||||||||||||||||||||

| * Terms: T/T 50% Deposit 40% Before Shipment 10% One Month After Installation |

| Model | SL-200 | SL-300 |

| Coil Width (mm) | 25-200 | 25-300 |

| Lamination Thick (mm) | 0.10- 0.50 | 0.10- 0.50 |

| Hole Size (mm) | 6-20 | 8-25 |

| Shearing burrs (mm) | ≤0.02 | ≤0.02 |

| Accuracy (mm) | +/- 0.01 | +/- 0.01 |

| Servo Motor | 3 | 3 |

| Hole Punch | 1 | 1 |

| Language | English | English |

| Power Required | 380VAC 50/60Hz (2.5KW) | 380VAC 50/60Hz (2.5KW) |

| Weight (Kg) | 1020 | 1100 |

| AC Voltage Regulator | Included | Included |

| Decoiler (LxWxH) mm | 1750 x 900 x 1540 | 1750 x1000 x 1540 |

| S Holder (LxWxH) mm | 2300 x 330x1100 | 2300 x 430 x 1100 |

| Cutting Unit (LxWxH) mm | 1600x850x1400 | 1600x900x1400 |

| Stainless Table (LxWxH) mm | 1200 x 750 x 750 | 1200 x 750 x 750 |

| Floor Space (LxW) Meter | 6.85 x 1.05 | 6.85 x 1.15 |