* ID:10-80mm / OD:100mm(mix) / Width:5-30mm * High Speed, Fully Automatic Toroidal Core Winder 5 Panasonic Servo Motors * High Reliability and Compact Design * Equipped with Laser Welder * Low Operating Cost: Tooling and Maintenance * High Precision @ Tolerance +/- 0.10mm * Training at SUMWIC (2 Days) * Warranty: Hardware(One Year) Software(Lifelong)

|

Introduction |

|||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

|

The RC Series is a high speed fully-automatic toroidal core winding machine which incorporates many advanced design features. Designed in TAIWAN and assembled in China, the highest quality components and materials, and through the application of an advanced design philosophy, very significant economies are provided in low running costs, high speed operation and low maintenance.

The integral welder is also under full automatic control of the HMI and PLC that brought into operation at the beginning and end of the transformer core winding cycle. The welding system has been selected to complement the associated engineering standards of the RC Series to give the highest degree of reliability. |

|||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| Laser Welder with Multi-Core Winders | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

|

One Laser with One Winder (1:1) For In-house usage, small production and sample making purpose.

One Laser with Two Winders (1:2)

One Laser with Three Winders (1:3)

One Laser with Four Winders (1:4) Video For Massive and variety core production. You can choose any four different or same model of core winders. For example: Two TC-15, One TC-40 and One TC-80 with a 4-outputs of Laser Welder. |

|

||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| Laser Welding System | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

|

Laser beam provides a variety of ways to join metals: it can join work pieces at the surface or produce deep welds. It can be combined with conventional welding methods. The technique is used to join multiple pieces of metal through the use of a laser. The beam provides a concentrated heat source, allowing for narrow, deep welds and high welding rates. The process is frequently used in high volume applications, such as in the automotive industry. It is also used in silicon steel spot welding. During spot welding, the heat-affected zones and the complete heating of the component are still considerably less than arc, plasma and TIG welding. The supply of energy can be well monitored, regulated and maintained or precisely controlled. * Laser transferred by 5 meters fiber cable which expand working area of machine.

* Regular Service Parts: ** Protect Mirror (Every Three Months) ** Xenon Lamp (Every Year)

|

|

||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

|

Panasonic Servo Motor |

|||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

|

* 5 Panasonic High-Speed Servo Motors Achieves 2kHz - the highest response frequency in the industry. In addition to its advanced control functions, the Panasonic Servo Motor features an LSI chip architecture that enables ultra-fast system operation. In view of its remarkable speed and superb positioning response, the Panasonic Servo Motor suitable for the most demanding systems. Furthermore, its outstanding response times drastically reduce vibration. Features a more compact motor that weighs considerably less. Both the large and the compact motor types have been overhauled, and the core has been successfully redesigned and scaled down. The integration of an innovative compact encoder has resulted in a 10% - 25% (1 - 6kg) motor weight reduction in the 1kW-and-larger class compared to conventional motors. For more information: https://www.panasonic-electric-works.com/eu/servo-drives-and-motors.htm |

|

||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| HMI (Human-Machine Interface) | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

|

* 10" Weintek (TAIWAN) i-Series Touch Screen. * Equipped with ARM9 400MHz CPU Greatly improve data processing and images display. * Language: English / Chinese For more information: http://www.weintek.com/globalw/Default.aspx# |

|

||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| SMC Air Cylinders, Equipment and Airline Connectors | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

|

SMC airline products are the only pneumatic components on SUMWIC TC-Series. SMC products are designed for precision performance and reliability. SMC's airline equipment provides unsurpassed sensing, regulation and filtration performance for the pneumatic system. With large range of pneumatic preparation products, the system can provide the clean dry air necessary to achieve the peak performance required by the fluid power system. The SMC's connectors simplify the plumbing of all the components. SMC's innovative one-touch and uni-thread one touch fitting technology provides dramatic time savings during the installation of both air fittings and pneumatic flow controls. For more information: http://www.smcusa.com/smc.aspx |

|

||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| De-Coiler | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

|

* RC100-30: ID 230- 310mm / OD 700 mm (Max.) * RC-250-100: ID 460- 510mm / OD 1000 mm (Max.) |

|

||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| Optional | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

|

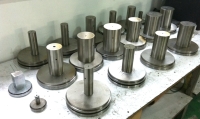

ID Tools (Inner Diameter) Professional design of inner diameter tools allow the winder to produce toroidal cores efficiently and precisely. One set of ID Tool is included with the machine. Depending on customer's requirement, different sizes of ID Tools can be made.

|

|

||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

|

|

|

||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

|

AC Voltage Regulator (10KVA) |

|

||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

|

C) Service and Payment Terms |

|||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

|

(C1) Overseas Standard Packing |

|||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| * Guarantee: No scratch and rust during long-range transportation 1) Applying Anti-Rust Oil 2) Covering with stretch Film 3) Covering aluminum air bag 4) Vacuuming air bags 5) Boxing all the pallet 6) Loading to the Container |

|

||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| (C2) Parts and Accessory | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

* Above items will be included in oversea project. |

|

||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| (C3) Service / Warranty | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| * Service Centers are available in India, China and Taiwan. Customers in these region can receive quick support and service. We also give quick response to customers in other region by on-line training or sending engineer on-site. * We offer On-Site Installation (One Day) On-Site Training (One Week) * Hardware Warranty: One Year Software Warranty: Lifetime |

India Service Center |

||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| (C4) Payment Terms | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| * Terms: T/T 50% Deposit 40% Before Shipment 10% One Month After Installation |

|||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| Model | RC100-30 | RC250-100 |

| Width (mm) | 5 - 30 | 20 - 100 |

| O/D (mm) | 100 (Max.) | 250 (Max.) |

| I/D (mm) | 10 - 80 | 35 -230 |

| Material Thickness (mm) | 0.15- 0.50 | 0.15- 0.50 |

| Shape | Toroidal | Toroidal |

| Servo Motor | 5 (Panasonic) | 6 (Panasonic) |

| Accuracy (mm) | <0.1 | <0.1 |

| Welder | Laser | Laser |

|

De-Coiler I/D Range (mm) Payload (Kg) |

230-330 150 (Max.) |

460-512 1000 (Max.) |

| Power Require | 380VAC

50/60Hz 0.8 KWH |

380VAC

50/60Hz 1.2 KWH |

| Size LxWxH (mm) | 1500x1000x1640 | 1950x1400x1800 |

| Weight (Kg) | 850 | 1750 |

| Language | English | English |

| AC Voltage Regulator | Optional | Optional |

| Air Compressor | Optional | Optional |